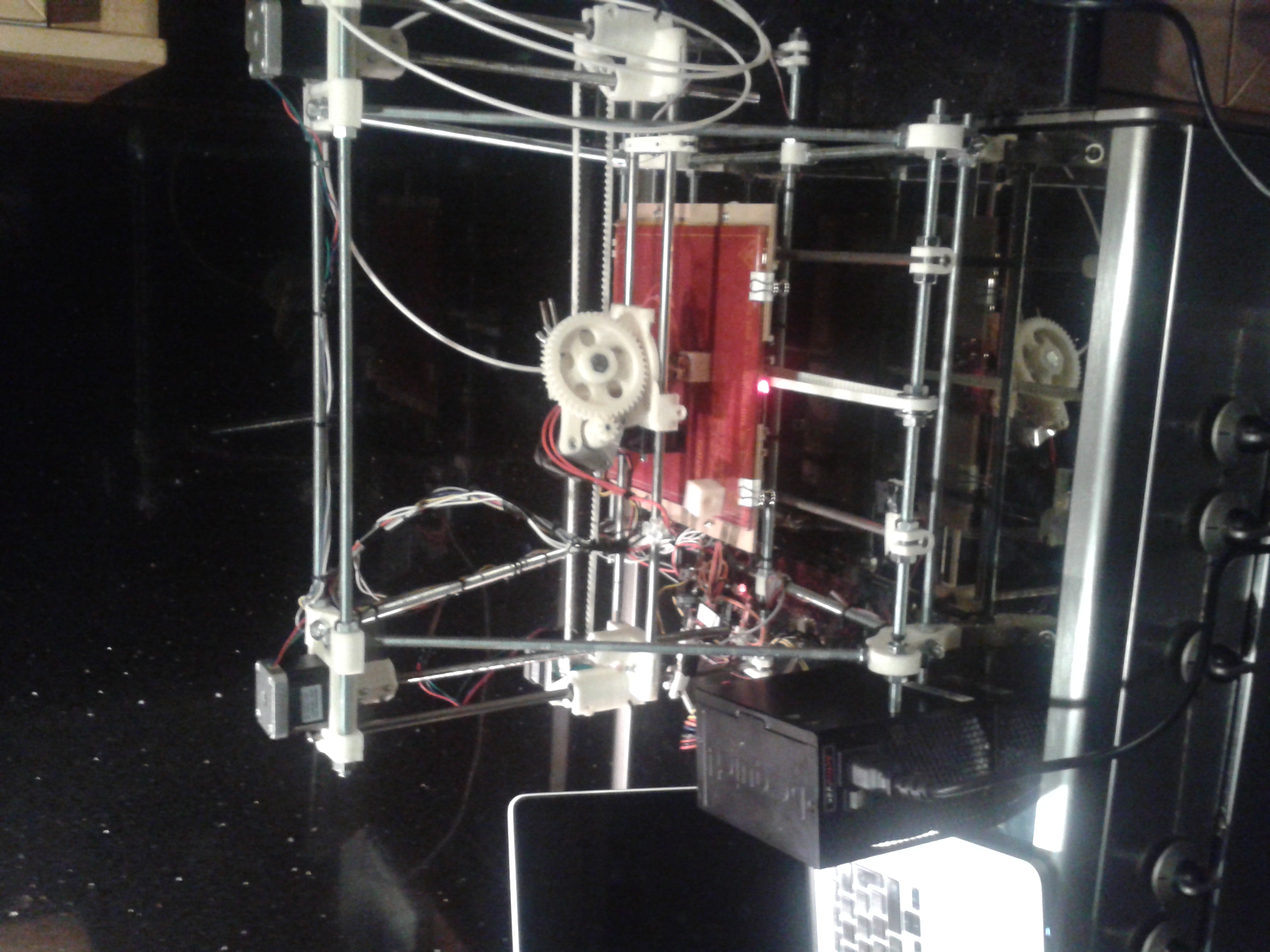

3D Printer Farm nearing completion

Written by Walter Schreppers on 12/2/2013

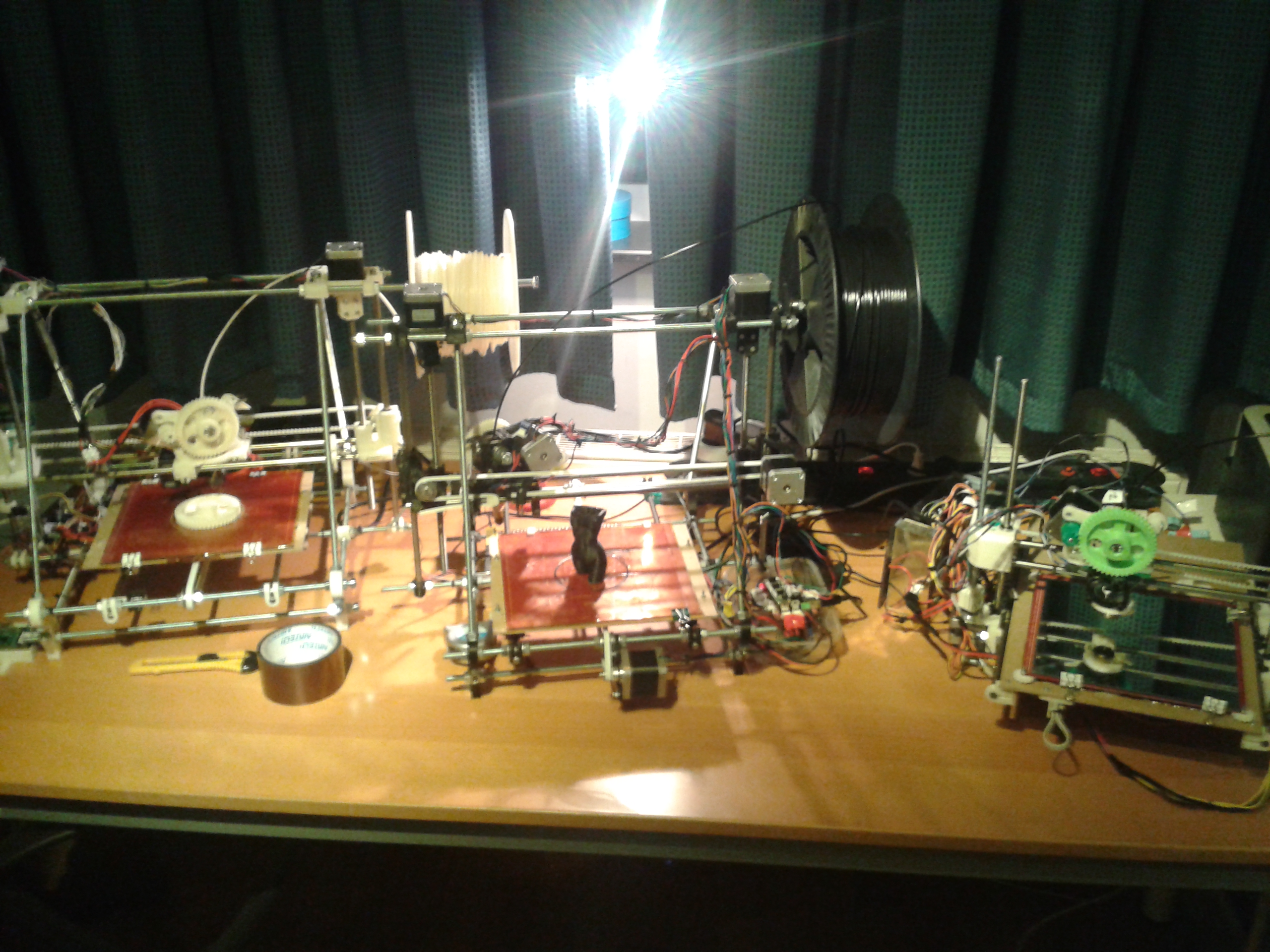

My 3 Fully callibrated printers running now with printerface :

Little history on how I got to this point:

Little history on how I got to this point:

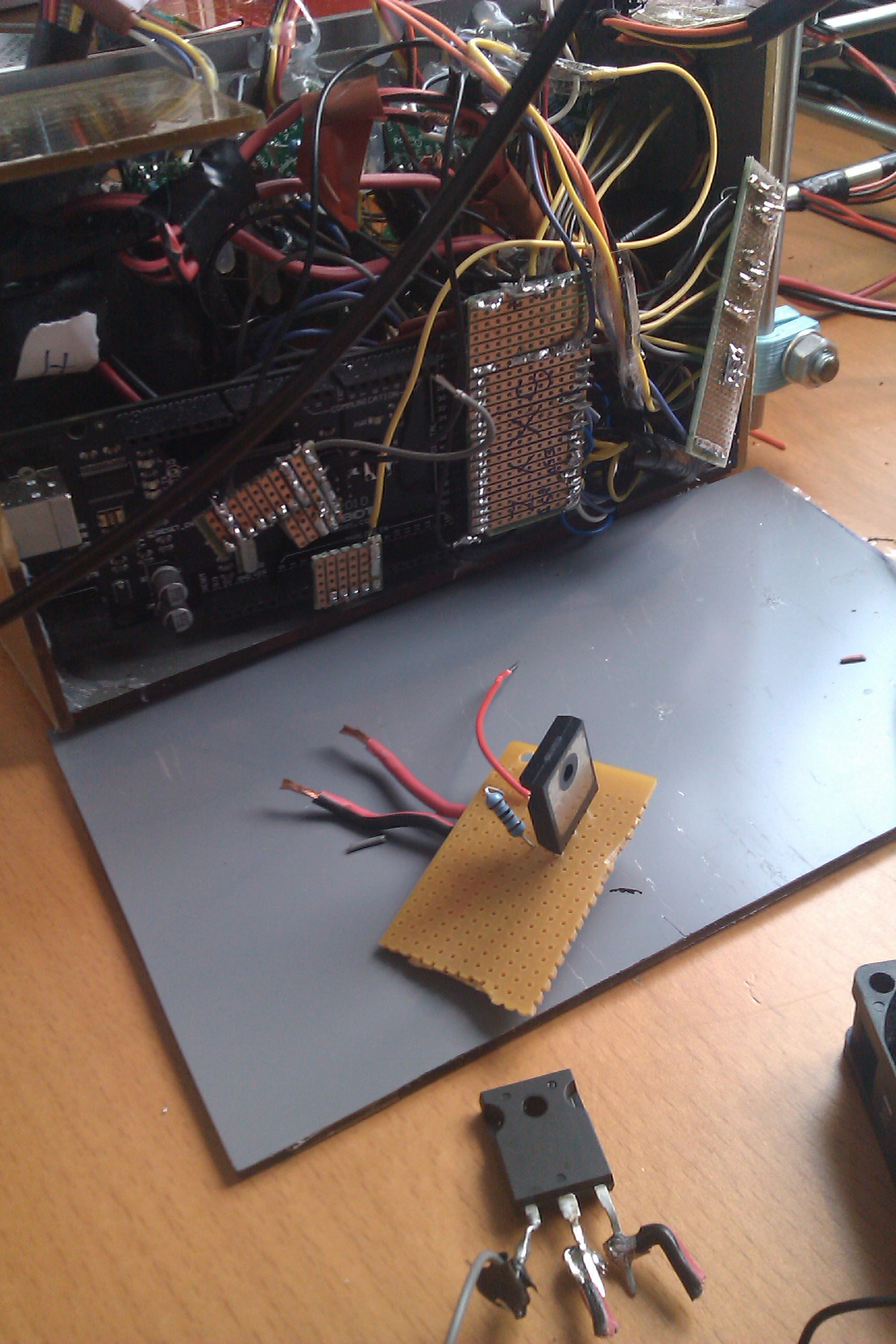

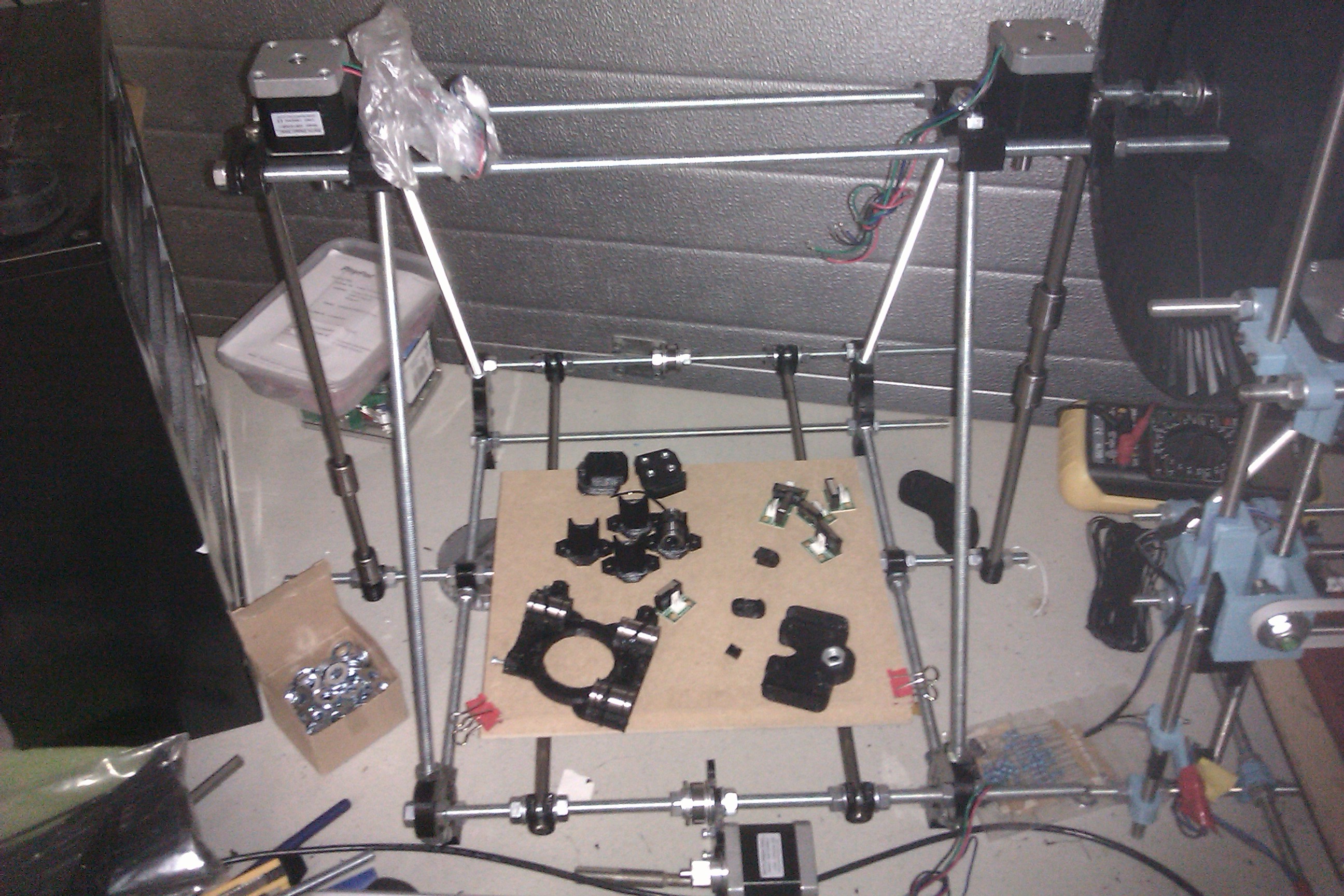

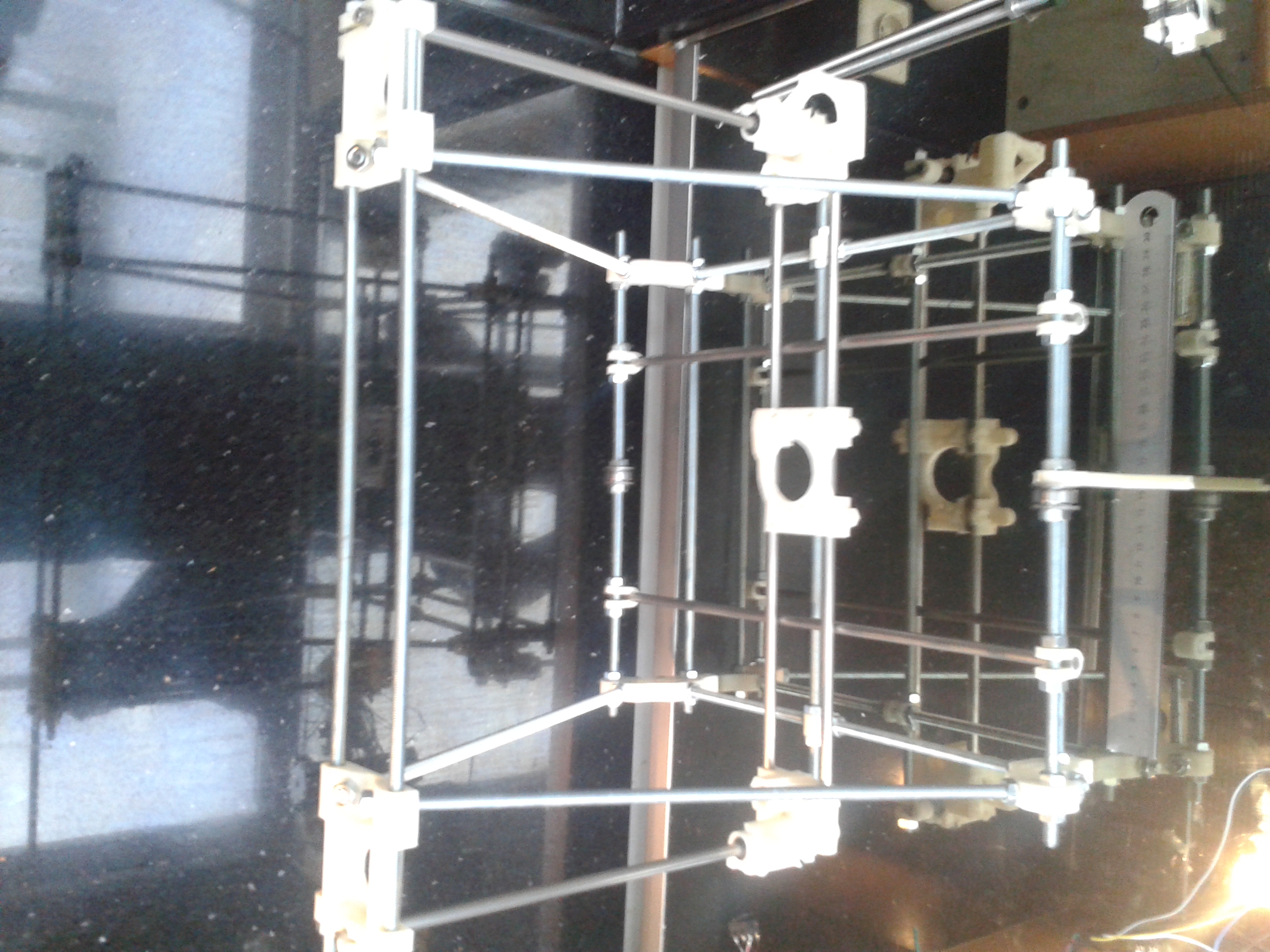

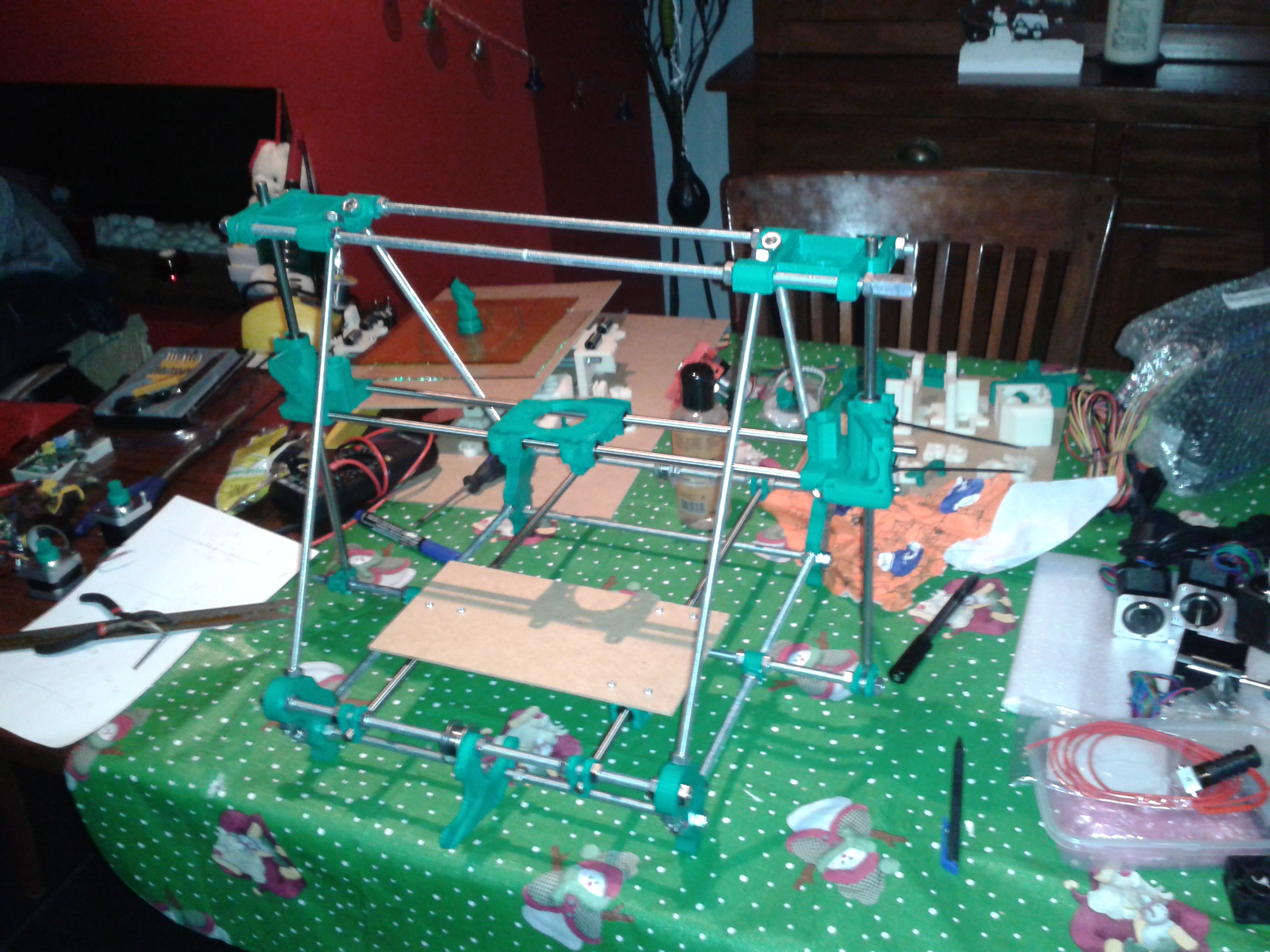

I started with a blue prusa version 1. This was with felt tips and during the skeinforge days, was a major challange to get working good enough to print new parts. Problems with it where the felt-tips instead of lm8uu bearigs are a real pain as it required constant recallibration of platform because the felts loosen during prints. I also did not have a heatbed in the beginning + I soldered my own electronics from scratch. A lot of it just on small strips of protoboard which were then added deadbug style onto an arduino mega.

In the picture you can see the mosfet that drives the heated bed which ofcourse did not work the first time and I had to go buy a new heftier one. But after that this worked really nicely and powered my heated bed which would allow me to print ABS parts which in turn would allow me to truly start replicating new printers in my own home.

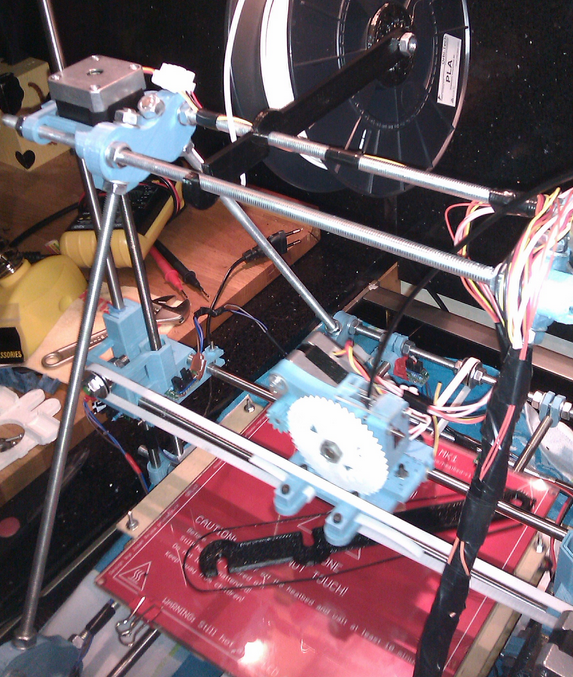

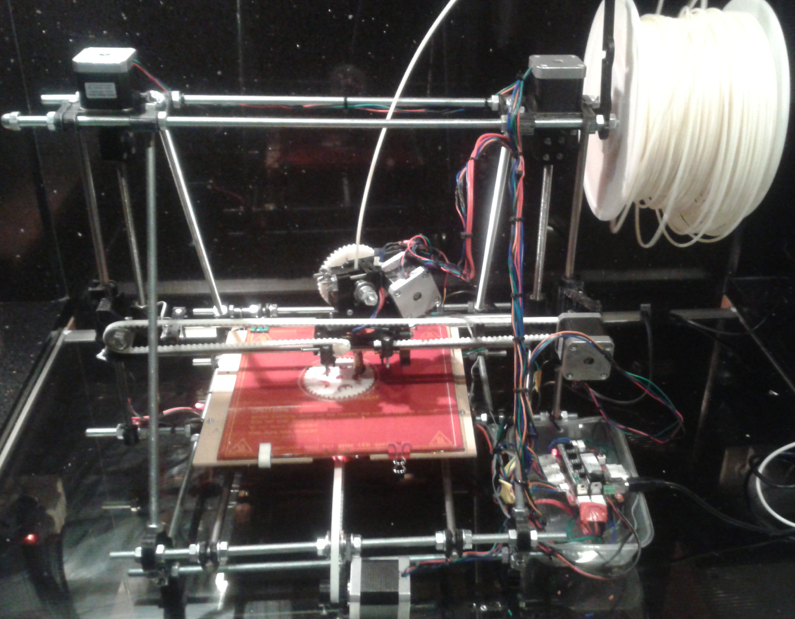

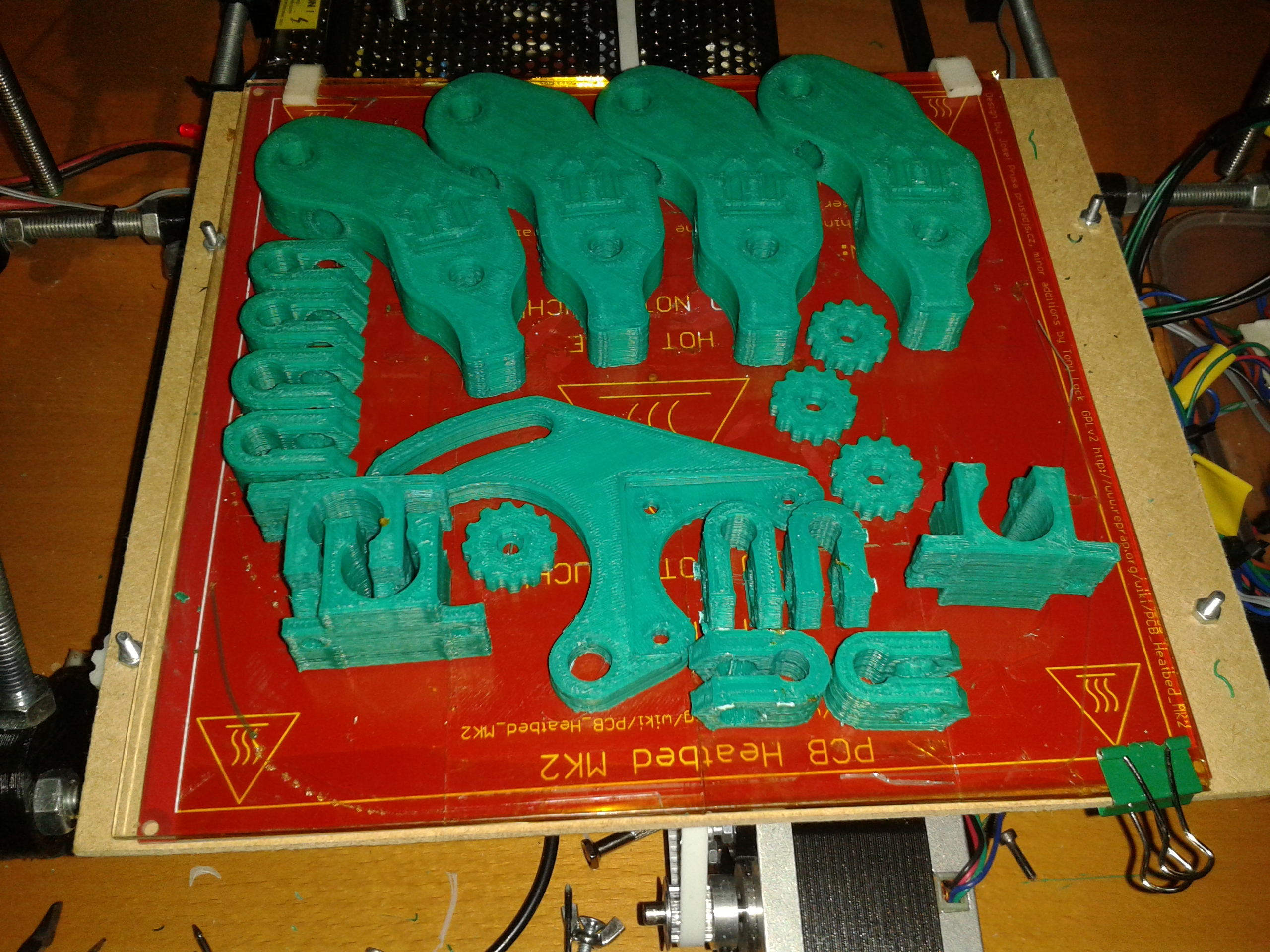

To make things worse I had 3 different hot-ends that either broke or leaked. First challange was making a new gear because the original one was warped and caused long prints to fail:

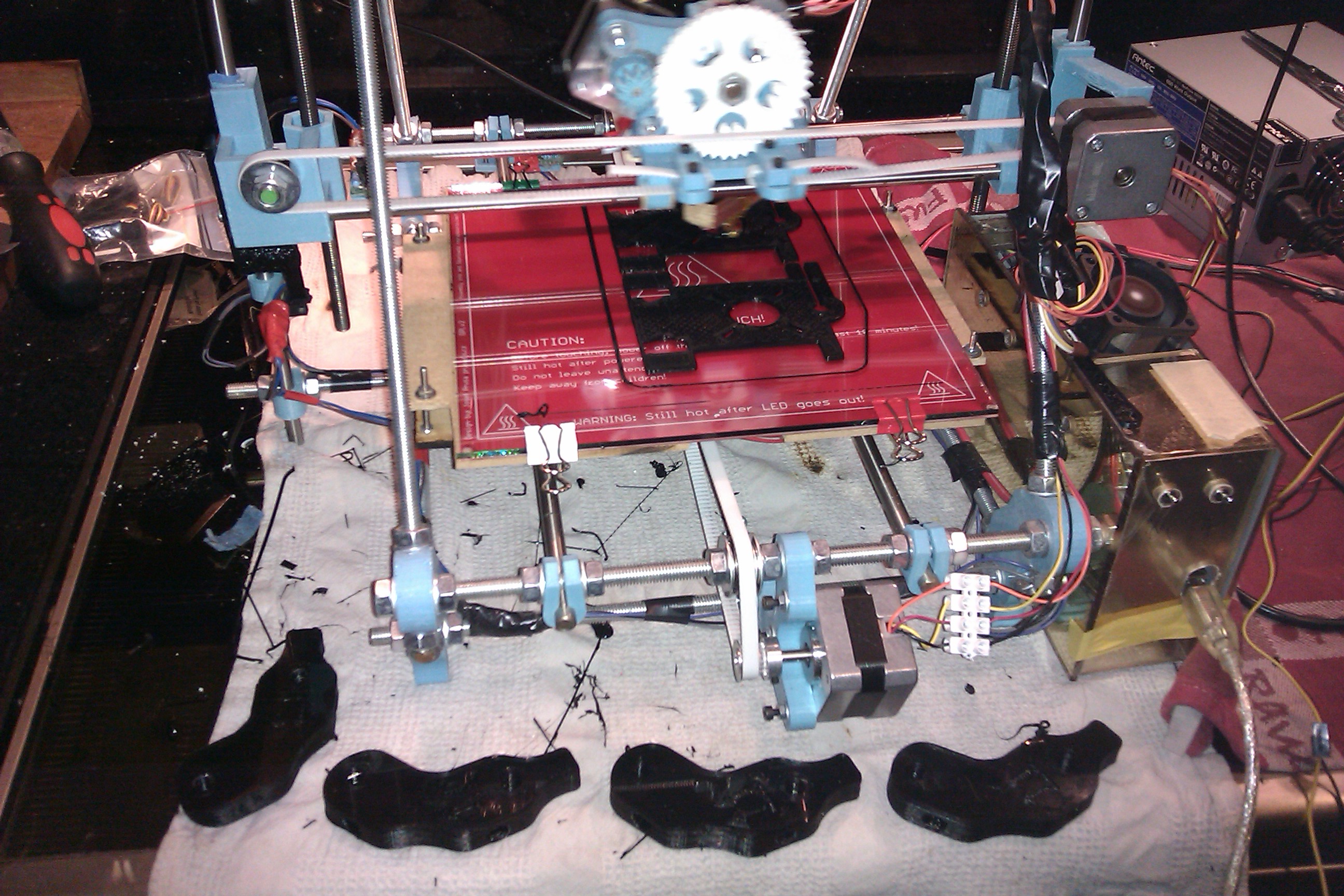

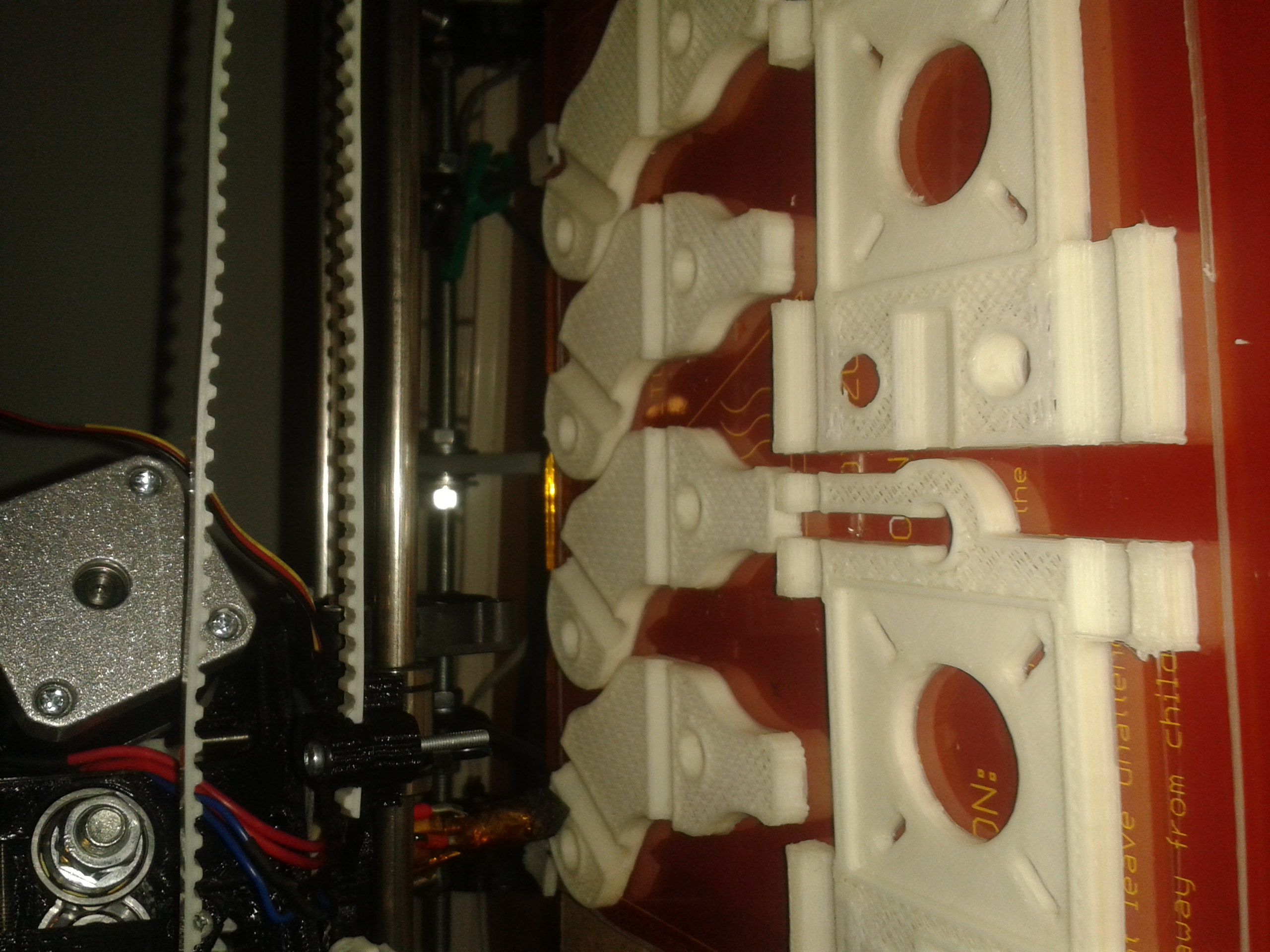

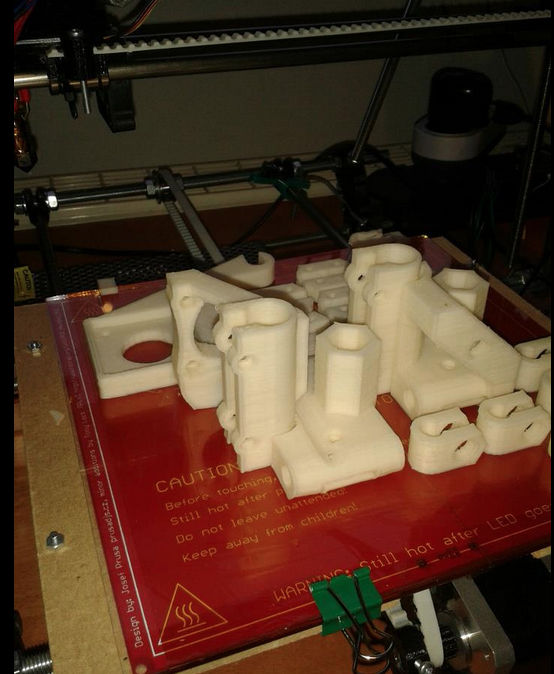

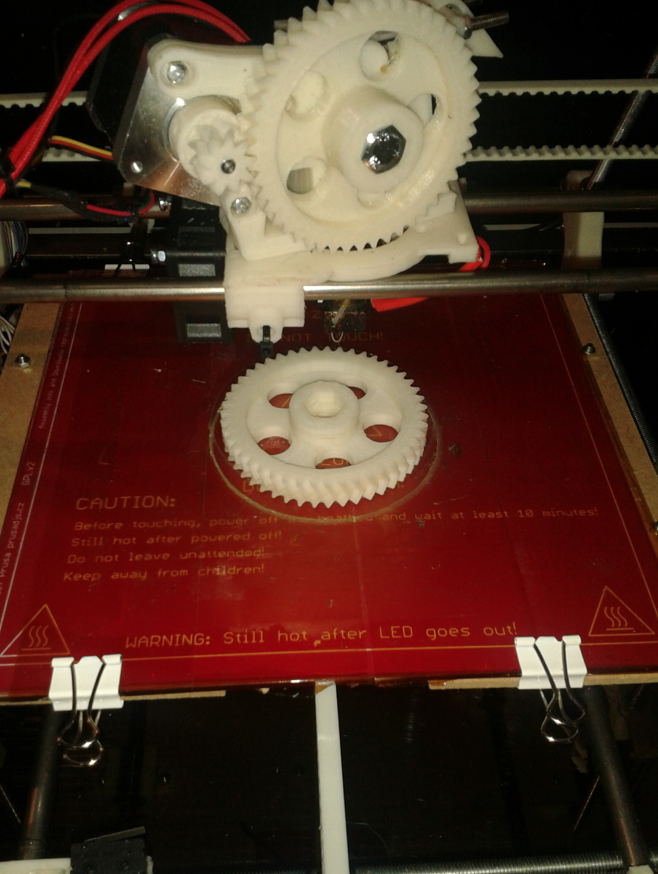

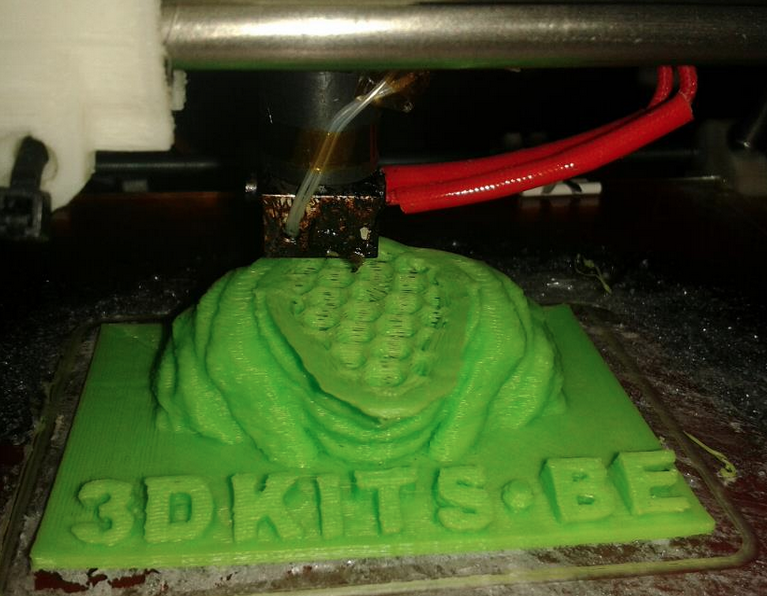

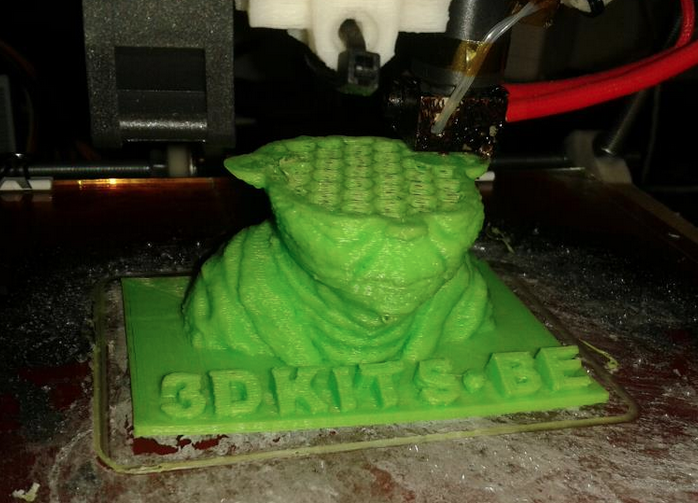

Printing a spool holder here, as my blue version was starting to print reliable. You can also see here the red heated bed is in operation and I switched from pla to abs. I did however mostly print in my kitchen which allowed me to use the 'built in fume extractor' that is present for cooking ;)

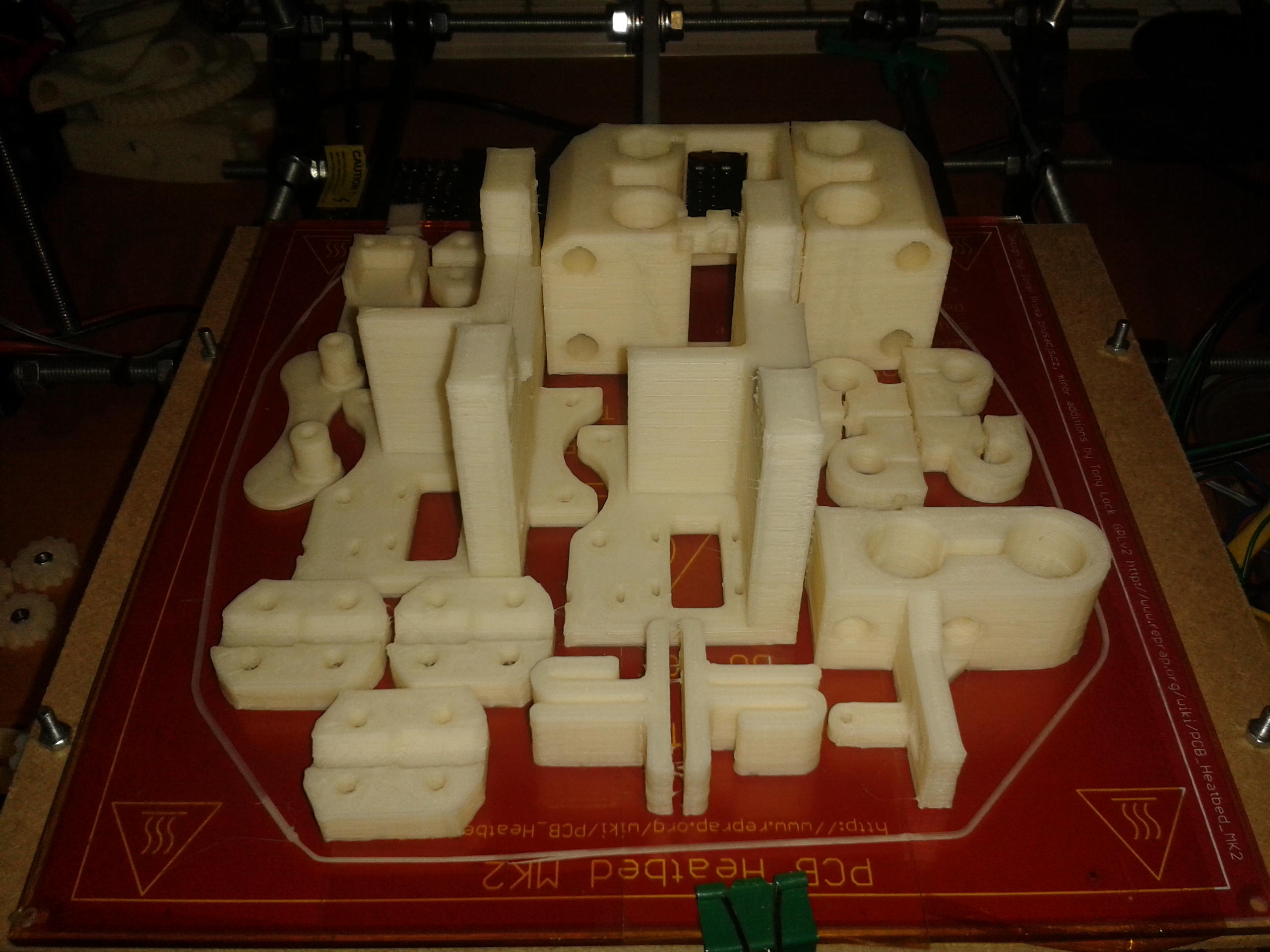

On this second reprap I printed the WalleBOT v2 (white one in the middle):

On this second reprap I printed the WalleBOT v2 (white one in the middle):

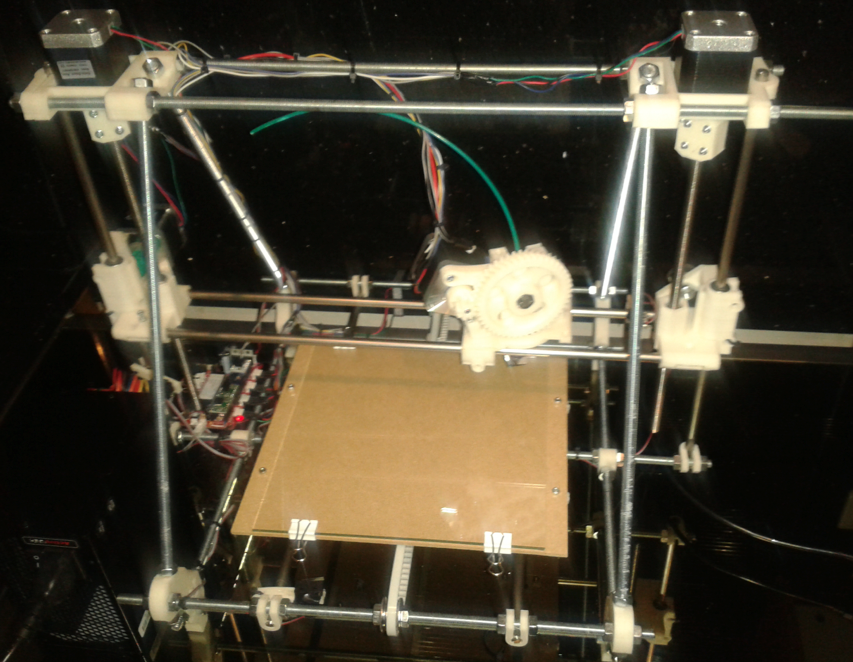

Eventually I sold the blue prusa frame and upgraded all but the black one into newer iterations (one suitcase printer, another prusa but this time a MK2 version). The black one I kept to this day as it was my truly homegrown printer from scratch that actually performed really well. It printed using 3mm filament and I keep it around whenever I stumble upon a cheap 3mm filament spool. All my newer printers however switched to 1.75mm filament as this allows for printing with an extruder which is not geared down and overal is more reliable and is easier to calibrate.